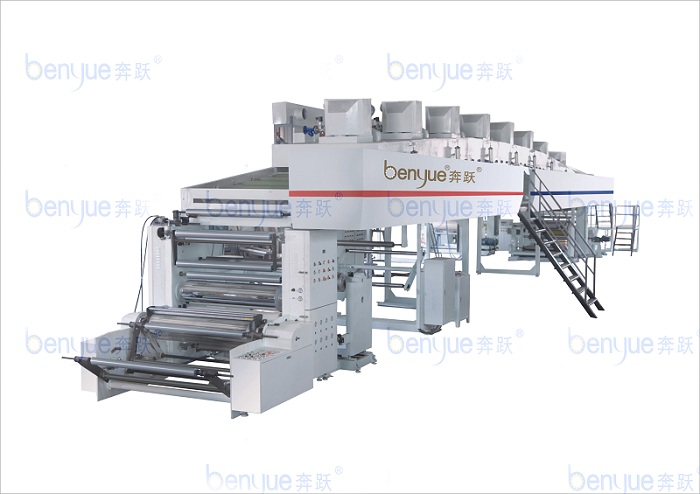

TB-800 double side conducting film coating machine

TB-800 double side conducting film coating machine:

一 Function

we draw into foreign advanced coating machine technology and together with our own many years of experience . it widely used in the production of any kind of release film

二 Parameter

| Type | TB-800 |

| Coating method | Gravure coating |

| Coating width | 800mm |

| Unwinding dia. | Ø800mm |

| Rewinding dia. | Ø800mm |

| Volume form | Two layer oven, uper layer |

| Oven length | 10m, down layer 8m |

| Oven temperature | 10-100℃ |

| Work speed | 10-80m/min(material depending) |

| Machine speed | 120m/min |

| diamension | 12500×2600×5100mm |

| Machine weight | 18000kg |

| Total power | 32kw |

| Oven heating power | Heating, 130kw, working 90kw |

| Heating method | Electric |

三 Performance and Features

1 overall machine adopt 6frequency motor control, overall machine tension (unwinding, coating, traction, rewinding) adopt JAPANESE MITSHUBISHI PLC to control tension automatic , through user’s interface touch screen to control and display to improve machine tension reliability

2 independent unwinding frame, adopt magnetic powder auto-control tension

3 gravure coating method, coating doctor blade shaft adopt heavy double shaft machine independent moving, blade adjust by manual with pneumatic, angle adjust freely, coating quantity depend on the mesh of gravure roller, different coating quantity can change different mesh gravure roller.

4 two layer oven is uper 10m for 5section independent control, down layer oven 8m for 4 section independent control, heating adopt electric, hot air intake drying system, heater outset,heating pipe adopt stainless steel with cooling fin type, adjustable inner cycle air intake and out device, air intake and out with strong air , dry thoroughly

5 oven inner guide wheel is active synchronous with the mainframe, drive adopt synchronous belt drive guide wheel to assure synchronous to reduce material stretch and deformation, cylinder pneumatic open oven and film pass operation panel to facilitate the worker’s work .

6 the tension between coaitng roller and traction steel roller adopt float swing arm by PLC auto-control

7 auto-length and speed meter device

8 webguide adopt EPC air sensitive register to assure the trimness when rewinding

9 rewinding and unwinding adopt key type airshaft for easily operate when loading and unloading the material, air shaft take in/off adopt safety lock type

10 high presicion up press traction device, steel roller cooling adopt water cycle to make the film surface more smooth and neat. To reach good cooling effect.

11 rewinding frame is electric rotation double station, rewinding adopt frequency motor, vector inverter by PLC control

四 Remark

A according to the different requirements of the customers special the customized machine (limited width of 300-2000mm)

B rewinding and unwinding frame : manual lift up type single station, hydraulic lift type single station, electrical rotation double station, electrical chain climbing type double station, electrical rotation wheel pan type double station can be choosed by customer

C oven heating method: electric heating, conduction oil heating, steam heating etc can be choosed by customer

D coating method: gravure roller coating, double rollers coating, three rollers coating, five rollers coating, comma blade coating, air knife coating etc can be choosed by customer

E work speed is proportion with coating material quality, coating thickness, oven length, drying temperature

五 Technological process

Unwinding-coating unit- drying unit-traction unit-rewinder

Through the above understanding, you should have a more understanding of coating machine, laminating machine, gravure printing press, Slitter, if you have other questions, you may contact our online customer service:+86-13958857367。

Relevant information

- [2020-12-12]How to reduce the energy consumption of the coating machine

- [2020-12-12]The digital display micro adjustment function of the adhesiv

- [2020-12-12]What is the significance of the development of the coating m

- [2020-12-12]The market capacity of the coater in China

- [2020-12-12]Do you know what the use of the coating machine is?

- [2020-12-12]What are the cautions for the use of the coater?

- [2020-12-12]Common fault and elimination of coating machine

- [2020-12-12]TB-1500 Surface modification coating method for coating mach

- [2020-12-12]Technology and technology application of hot melt adhesive c

- [2020-12-12]The safety operation process of the servo control system of

- [2020-12-12]The composition and difficulties of the production process o

- [2020-12-12]What is the operation of the coater for production?

- [2020-12-12]How to clean the coating machine

- [2020-12-12]The working principle of the coating machine

- [2020-12-12]Explanation of the processing of coating machine before coat

Recommendation scheme

- TB-1200 double side coating laminating machine

-

Feature:TB-1200 double side coating laminating machine 一 Functionwe draw into foreign advanced coating machine technology and together with our own many years of experience .the machine adopt both side gravure coating method, it widely used in the ...

- TB-1600 canvas/photopaper coating laminating machine

-

Feature:TB-1600 canvas/photopaper coating laminating machine 一 Functionwe draw into foreign advanced coating machine technology and together with our own many years of experience .it adopt comma blade and double roller two kind coating method, it widel...

- TB-1300 multi-function coating laminating machine

-

Feature:TB-1300 multi-function coating laminating machine一 Functionwe draw into foreign advanced coating machine technology and together with our own many years of experience .it adopt comma blade blade and gravure roller two kind coating method,comma bl...

- TB-800 double side conducting film coating machine

-

Feature:TB-800 double side conducting filmcoating machine:一 Functionwe draw into foreign advanced coating machine technology and together with our own many years of experience . it widely used in the production of any kind of release film二 ParameterT...

Ranking of similar articles

- Explanation of the processing of coating machine before coat

- Common fault and elimination of coating machine

- The working principle of the coating machine

- What is the operation of the coater for production?

- How to clean the coating machine

- The composition and difficulties of the production process o

- The safety operation process of the servo control system of

- Technology and technology application of hot melt adhesive c

- TB-1500 Surface modification coating method for coating mach

- What are the cautions for the use of the coater?

Latest information articles

- How to reduce the energy consumption of the coating machine

- The digital display micro adjustment function of the adhesiv

- What is the significance of the development of the coating m

- The market capacity of the coater in China

- Do you know what the use of the coating machine is?

- What are the cautions for the use of the coater?

- Common fault and elimination of coating machine

- TB-1500 Surface modification coating method for coating mach

- Technology and technology application of hot melt adhesive c

- The safety operation process of the servo control system of